aquaculture equipment, seed and oysters

Pearlception 2.0

Grade, sort and pack millions of oysters

Description

Pearlception 2.0 is the first high-speed, laser-guided oyster processing system designed and built in the U.S. This revolutionary model offers unprecedented oyster sorting and grading capabilities together with an intuitive, operator-interface system. Pearlception automates sorting, increases productivity, prevents waste and delivers an outstanding ROI.

Overview

Incorporating functions of sensing, actuation and control, Pearlception 2.0 is the first “smart system” processor designed to grade, sort and package more than 6,000 oysters an hour. Using real time data and predictive modeling, Pearlception is capable of semi-autonomous operation using preset parameters of length and width or length and volume, grade positions, box counts, and totals and provides real time data on grades, box counts, and totals.

Pearlception 2.0 Features

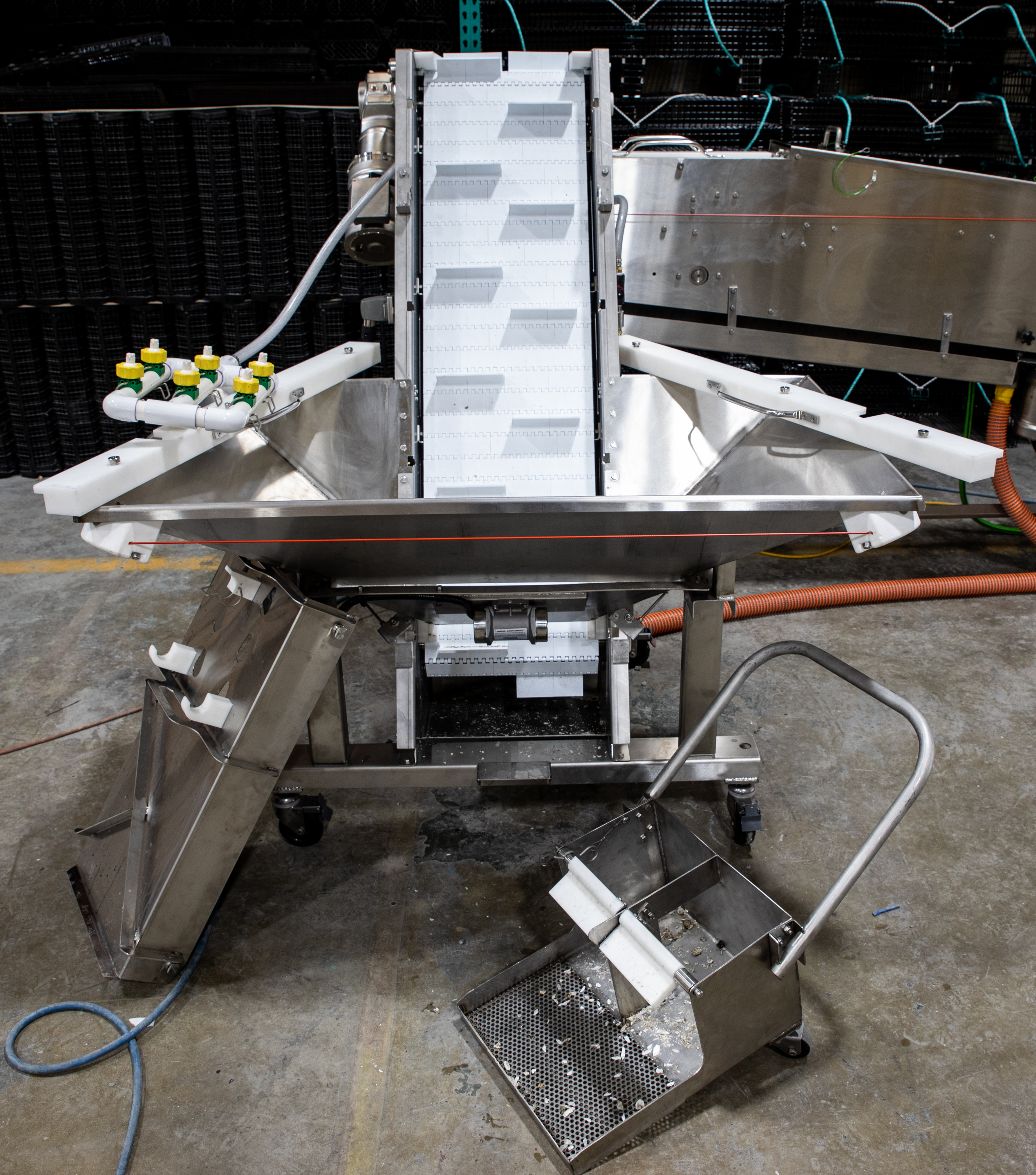

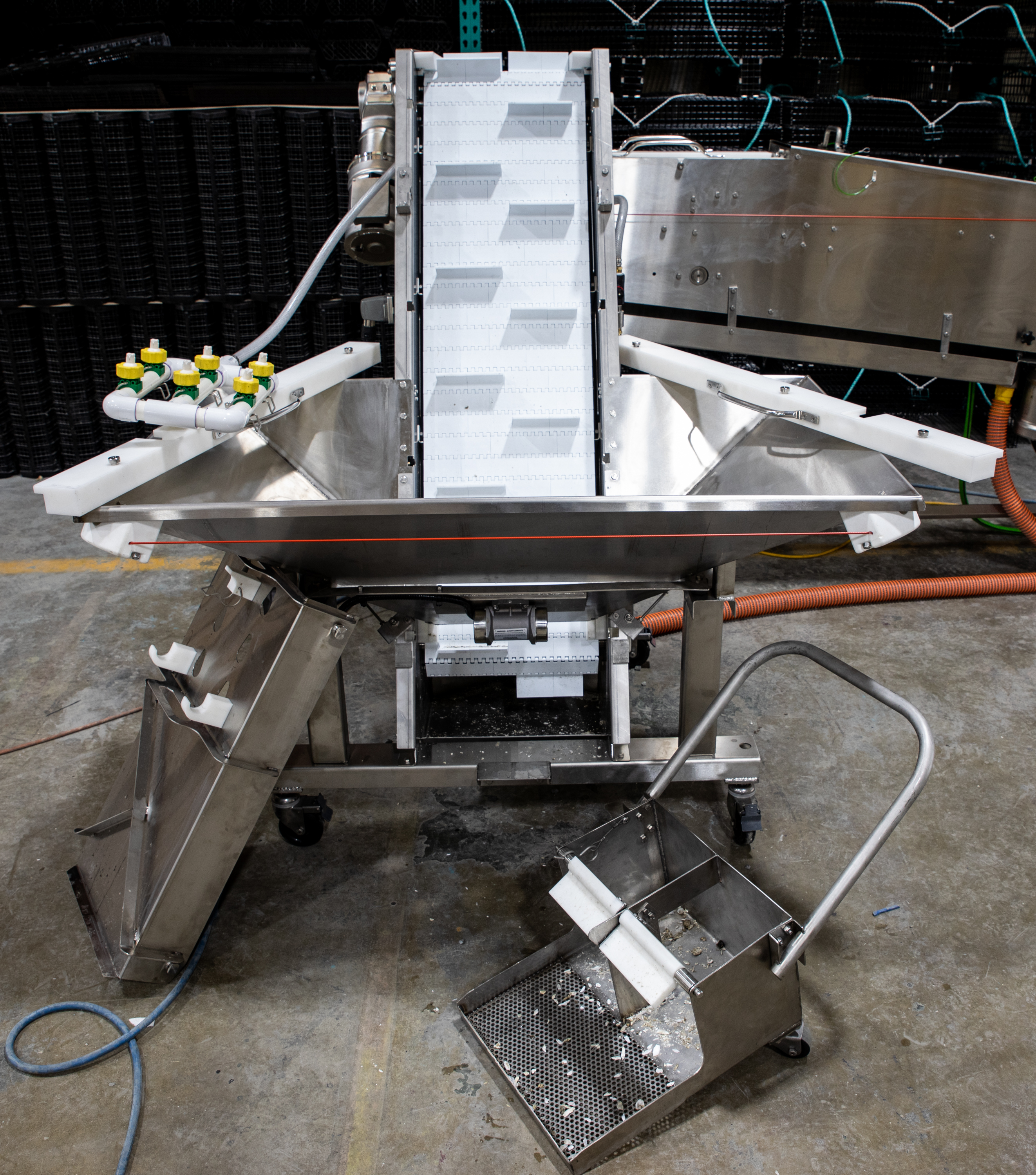

- Vibrating, self-loading up-feed features quickly moves oysters up a conveying elevator with staggered flights for steady loading

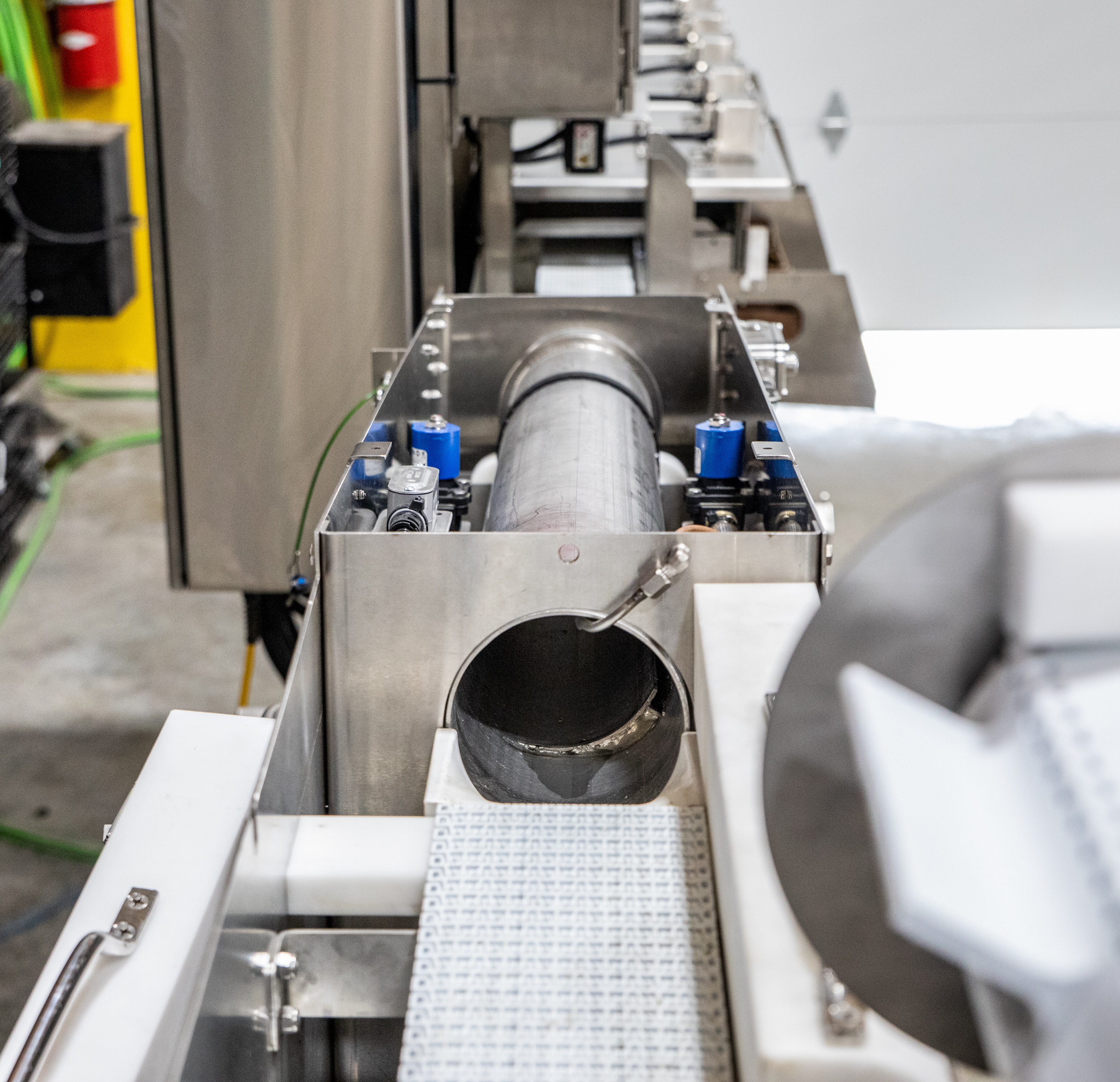

- Cross-feed delivers oysters to the singulator tube where they are turned on two points and accelerated onto the conveyor for precise laser grading

- Six air nozzles move oysters quickly and gently to one of six pre-set stations for boxing or bagging

- OysterLogic program tracks graded oysters and stops system with alarm if no boxes are available allowing operator to replace and restart system with no product loss

- Integrated sensors confirm and guarantee oyster count; stations flash green once predetermined number of oysters are counted

- Large touch-screen monitor and intuitive interface features seven distinct screens to configure, operate and manage processing for different levels of authority

Benefits

- Stores 20 oyster configurations with up to three grades each

- Stainless steel construction with all washdown duty components

- Wide removable rails on up-feed and singulator allow quick and easy cleaning

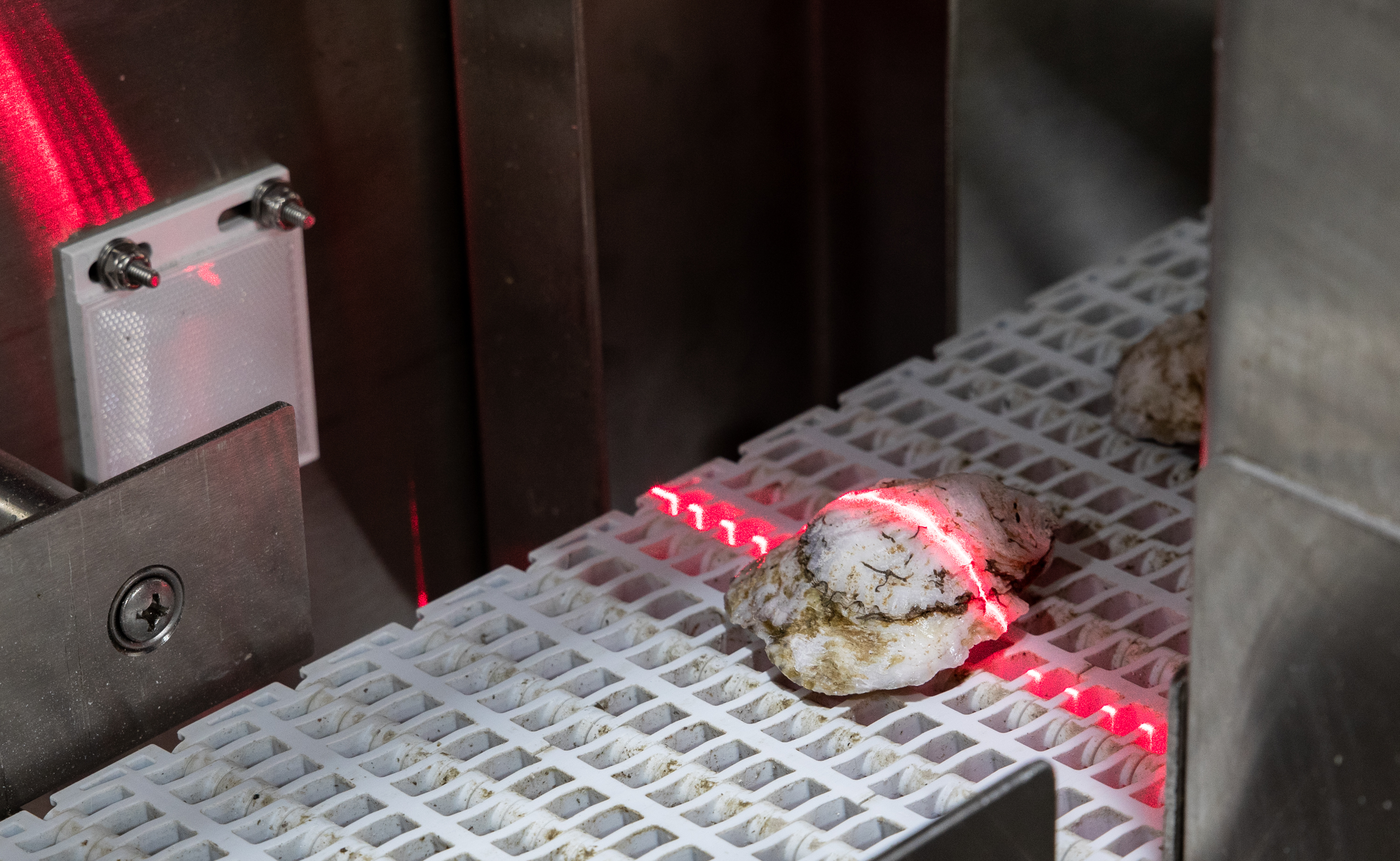

- Laser scanning precisely grades oysters by length/width or length/volume

- Verification sensors ensure accurate box or bag count

- Premium components include Allen-Bradley variable frequency drives, programmable logic controller, human machine interface, starters, push buttons, circuit breakers and terminal blocks and SICK scanning laser, trigger eye, and confirmation sensors

- Safety redundancies include E-stops and integrated cable pulls to halt all system motion in an emergency

- Remote log-in and monitoring with eWON Cosy secure access provides continuous real-time data collection and statistics

- Debris catch pan with integrated belt flight flaps detaches from bottom of conveying elevator for easy cleaning and washdown

- Operates in temperatures as low as 40*F degrees

- OysterLogic maintains box counts and totals when system resets following e-stop

- Pearlception stations can be configured with additional hardware to allow for conversion from boxes to baskets or bags. Call for pricing.

Price

- Call for pricing

- Lease options possible

- Price includes delivery, set-up, training and service program

Terms

Contact

sales@blueoysterenv.com

(410) 397-3664 (Office)