Oyster Farming

Overview: Harnessing Tide, Time & Tradition

We proudly raise our delicious, sustainable oysters on Maryland’s Eastern Shore. Using methods rooted in tradition – and elevated by science and sound management –

we grow millions of premium oysters served by top restaurants and seafood markets

. From tide to table, it takes approximately 18-24 months to grow our plump and briny bivalves. We farm on two leaseholds off the Chesapeake Bay using surface grow-out techniques. Our lease closest to Hoopers Island produces oysters with an average salinity range of 15-18 ppt. Slightly saltier, our oysters grown further south off of Fishing Bay average a salinity of 17-20 ppt.

Broodstock

Let’s begin with a little biology 101. We grow Eastern Oysters (Crassostrea virginica) native to the North American waters of the Atlantic and Gulf of Mexico. They’re disease-resistant, natural triploids originating from broodstock selectively bred at the Virginia Institute for Marine Sciences (VIMS).

What makes them unique? Triploid oysters have three sets of chromosomes and offer two important advantages in their lifecycle. Because they’re sterile (due to their uneven chromosome number), they don’t expend energy reproducing during the summer

months or lose body weight once they’ve spawned out. They remain firm and plump and grow to market size much faster than a diploid oyster (12 to 18 vs. 36 to 48 months).

Hatchery

It starts in our Crocheron, Maryland hatchery with conditioned broodstock selected based on our customers’ needs. .

Using a scalpel, the hatchery team gently removes and collects the gametes from the oysters. Sperm from tetraploid males (four sets of chromosomes) is used to fertilize eggs from diploid females (two sets of chromosomes) to create natural triploids. Fertilization takes place within minutes and cell division occurs over the next 24 hours. It’s a natural breeding process. As many as 115 million fertilized eggs are introduced to 1,500-gallon tanks in our rearing room.

The larvae are voracious eaters. And we feed them well. Four to eight times a day with different algae grown in our mass culture room. In two to three weeks, the larvae develop an eye-spot, a sign that they are ready to latch on to a substrate.

Nursery

Moved outdoors to our downwelling system at the Crocheron hatchery, the eyed-larvae are given ambient water with hatchery grown algae and finely ground oyster shell called micro-cultch. Once settled and attached to this substrate, within 24 hours they undergo metamorphosis and become seed.

When the oysters are about 500 micron or .5 mm, they are moved to a land-based upwelling system and fed unaltered ambient water for the first time. Their energy is focused on shell growth. After two to four weeks, they are graded and moved to baskets in a

floating upweller system.

One the oysters reach 6mm (~1/4 inch), they are placed in Hexcyl Baskets for approximately three months.

Grow-Out

When the oysters are about an inch long – approximately six months – they are placed in surface grow-out gear.

Tumbled by the tide in their protected baskets – the constant wave energy produces a deeper cup and denser shell – improving taste, quality and appearance.

These surface grow-out methods have many benefits. Ample sunlight, better water quality and constant motion create deeper cups for plumper oysters and better shell density for easier shucking.

During this final grow-out stage, we regularly pull, clean and grade the oysters. This promotes growth and ensures a deep cup and beautiful shell.

Management

We are committed to harnessing science, technology and nature for optimal farm management. To monitor our activities and inventory, we utilize Oyster Tracker , an exceptional software system that helps us decrease mortality and meet production goals.

By tracking our farm activities and oyster inventory in real time, we consistently produce more, high quality oysters.

Harvest & Processing

At 12 to 18 months the oysters are ready for processing, inspection and grading before going to market.

Our proprietary wet storage system provides a stable environment to hold oysters post-harvest to ensure freshness and quality. Dissolved oxygen is added to increase the oyster’s health and shelf life. The system also allows us to infuse salinity in the finishing process resulting in a considerably higher – 25-30 ppt – and brinier taste.

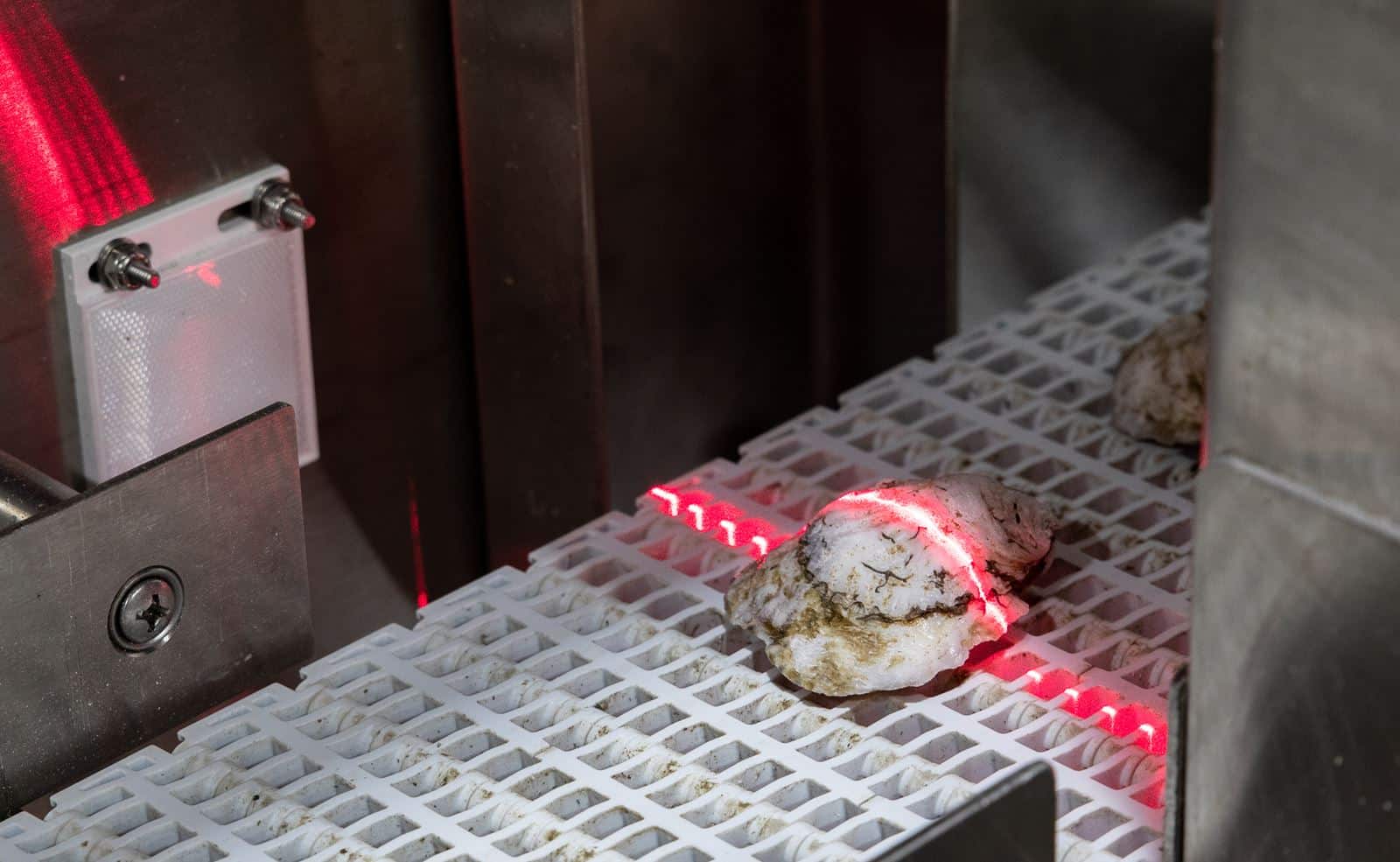

Our Pearlception oyster grader uses 3-D laser image scanning to identify the precise volumetric size of the oyster for packing.