Since the ancient Romans adopted growing oysters more than 2,000 years ago, farmers have looked for the best environment, practices and gear to produce their shellfish.

Thanks to emerging technologies, equipment, and grow-out methods, oyster farmers like Hoopers Island have developed a variety of cost-effective, proven techniques to produce the best tasting, fastest-growing oysters on the market.

As Hoopers’ oyster hatchery manager, we’ve had great success implementing three aquaculture best practices that significantly improved operations at our Chesapeake Bay farms.

Lifting Cages with Longline Systems

The first is an Australian aquaculture method pioneered “down under” that is changing the way many U.S. farmers grow oysters. This unique “longline” system utilizes posts spaced every 10 feet with clips placed at various heights depending on tidal ranges. A nylon rope with a polypropylene sheathing is rigged between posts and a rugged, plastic basket capable of holding up to 25 liters (6.6 gallons) is suspended from the line.

When there is limited shore access to use this system, we developed an alternative method that floats the Hexcyl baskets using a longline that is 100 percent subtidal.

Never coming out of the water, the system can be implemented at greater depths using a floating longline setup for oysters ranging from 6mm to market size.

Mapping Data to Measure & Monitor Conditions

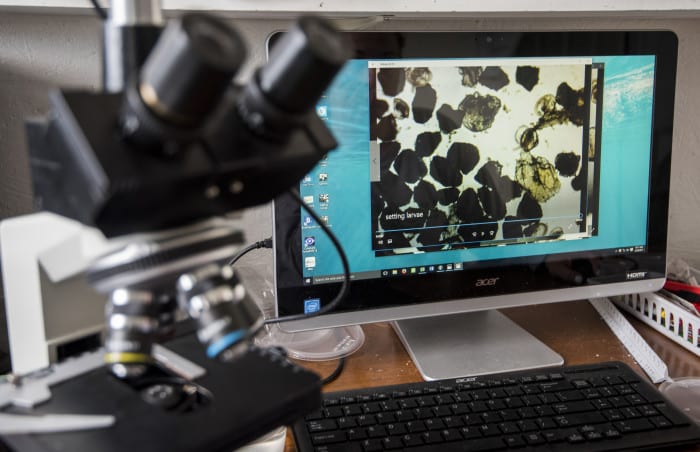

A second practice and growing trend we’ve successfully harnessed is using computer mapping technology to track oyster location, growth, survival, and quality throughout the grow-out process.

Looking to integrate data collection into daily operations, we wanted to monitor growth, grade and product location in real time from our smart phones and tablets.

After evaluating different software, we selected ArcGIS by ESRI. The system aggregates spatial and geographic data using a customizable collection form. ArcGIS allows us to capture and analyze growth trends whether we’re at the office, on the farm, or somewhere in between.

We are also applying this system to our nursery and hatchery to collect growth and survival data at every point of grow out. For example, we capture each individual grading event in our nursery and compile the data at the end of the season to track growth rates at various salinity levels and temperatures. This helps us increase our efficiency and yields throughout the year.

Graduating Grow-Out Gear

The third practice that has significantly helped us increase production is tailoring our gear type to match the growing environment and seed size.

In 2017, we began moving seed from a FLUPSY to floating gear at 6mm instead of 12mm. The result has significantly enhanced shell density and shape and increased growth rates and sorting efficiency.

As a waterman, I believe it’s critical for oyster farmers to stay on top of new trends, research and best practices in aquaculture. how these practices can be adopted on your nursery to increase yields, growth and quality.

If you’d like to learn more about our experience with longlines or grow-out gear, contact me by email or phone at (410) 397-3634.